Steps to Go from Prototype to Usable Device

I still haven’t purchased the IOIO board, but I wanted describe the common steps to go from prototype to usable or sellable device.

The steps are generally:

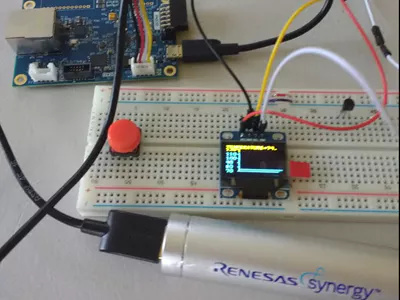

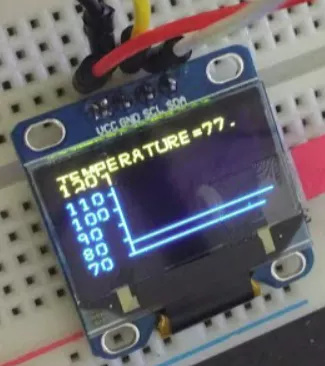

- Prototype working concept with breadboard

- Build prototype in one-off case with soldered PCB board

- Manufacture custom PCB board from design files with a small run of 10 boards

- Design custom 3D-printed case either at home or a service that takes 3D printer design files and sends you back the custom case

At this point, you’ll have a good-looking product that you can show to potential large volume customers or resellers. You can either stop there or work with a design house to build the product boards with tape roll components soldered on the board in the factory.

Feasibility Assessment

Prior to buying the IOIO board, I decided to look at the available resources to see if it would feasible to go from step 1 to step 5.

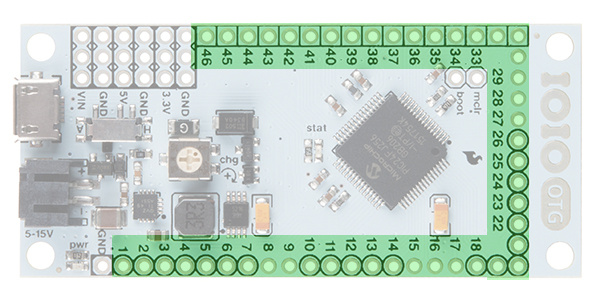

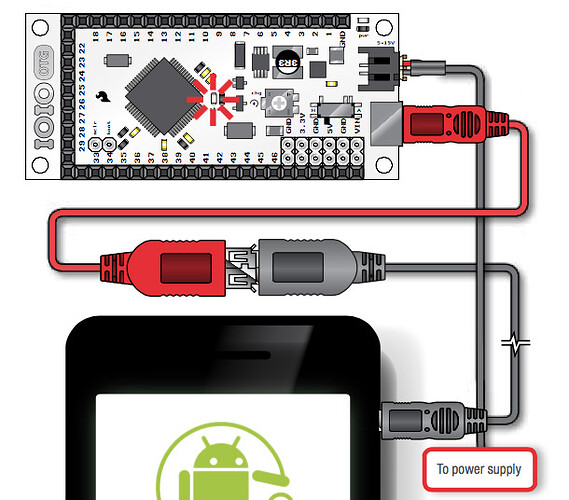

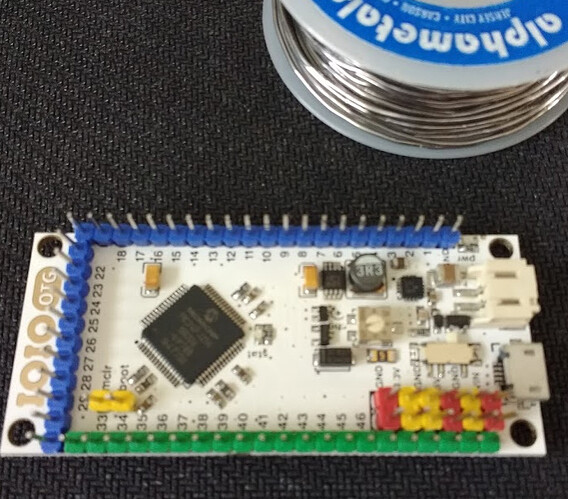

Building the prototype with the IOIO board is definitely doable as the board is specifically designed for prototypes. A large portion of the MCU pins are exposed through headers and you can easily connect to them.

There’s a great deal of information on the IOIO-OTG Board Wiki.

Some of the key things we need are:

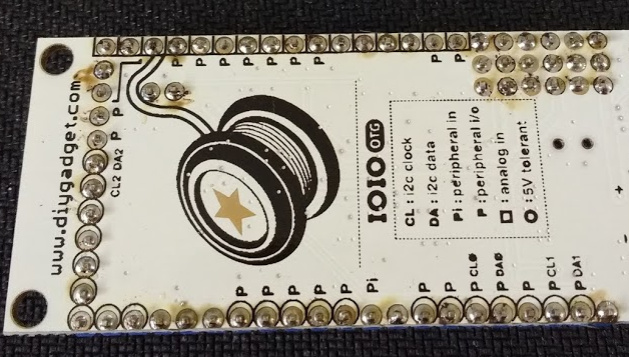

Instead of building your own board design from scratch, you may want to start with their design files. The CAD design files for IOIO OTG are on GitHub as Eagle PCB design files. Eagle is PCB design software that you can get as a free download from Autodesk.

Finding a PCB Manufacturing Vendor

The IOIO OTG is manufactured by both Seeed and SparkFun. Seeed has a PCB manufacturing service called Seeed Fusion. You can get boards for as low a $5 in small orders. An instant online quote is available for your design.

Community member @Serdnleb reported this on a generic PCB order, NOT a modified IOIO OTG board order. This example is just to give you a feel for lowest costs based on real-world community experience.

I’ve used Seeed Fusion service a few times in the past. They are especially good if you need several of the same board as they send 10 copies at very low price. The boards are very nice quality. I live in the UK and got the boards about a week after placing my order. If you need fast shipping you can go with DHL but is a bit more expensive.

My latest order from Seeed, to manufacture 10 pieces of 2−layer white PCB boards cost $4.9USD in total. This will cost $27USD in total to manufacture and ship to UK through DHL within 11 days.

June, 2017 @Serdnleb

Seeed has a good online document called PCB Design for Manufacture. I recommend you read this document prior to starting your design.

This is just for the PCB board.

The other costs are the PIC MCU, which is $7.49 in units of 1 on Digi-Key and other hardware such as the USB connector and the mounting connection to the THETA. Note that you probably won’t be able to solder the MCU onto the PCB yourself. You’ll need to work with the manufacturer to get it soldered on for you.

Alternative Designs

Although it’s unlikely that I’ll move forward with PCB design, I’d look at alternative designs before moving forward with the PIC MCU. In particular, the Renesas Synergy 124 is $5.30 per unit on Digi-Key and comes with these specs: ARM® Cortex®-M0+ Renesas Synergy™ S1 Microcontroller IC 32-Bit 32MHz 128KB (128K x 8) FLASH 64-HWQFN (8x8).

Unfortunately, it does not specify USB OTG features like the PIC chip, so I might have to go back to the PIC chip for simplicity. There is a discussion on USB OTG support in Synergy, but it seems like it may be more work than I’m looking for right now despite having two S124 dev boards on my desk.